|

|

|

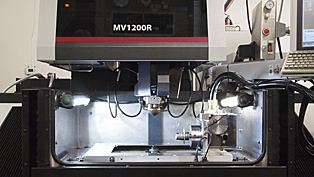

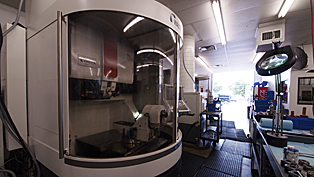

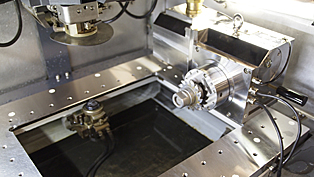

| MCC Tooling has grown from a small machine shop to a state-of-the-art manufacturing and reconditioning facility by providing superlative service to our customers. We specialize in reconditioning drills, reamers, end mills, taps and most other types of high speed rotary cutting tools. Using our advanced Walters CNC grinding equipment, we can keep your expensive cutting tools in "like new" condition at a fraction of the cost of purchasing a new tool. | Using our computer controlled Mitsubishi Wire EDM machinery, we are also able to manufacture special custom tooling for the medical and aerospace industries. If you need a specialized tool for your manufacturing process, we can make it for you. Even hard to work with materials like cobalt and carbide steels are not a problem for us. Our ability to design and manufacture custom tooling makes short run production economically feasible for many high-tech industries. | We know that your cutting tools are an essential part of your business. When your production lines are down, you aren't making money. That's why we offer fast turnarounds and are able to process rush orders day or night. When we receive your tools, they are identified, thoroughly inspected and then reground to the exacting tolerances you need using our five axis Walter CNC tool and cutter grinders. If you aren't satisfied with the results, the job is on us. |

|

|

|